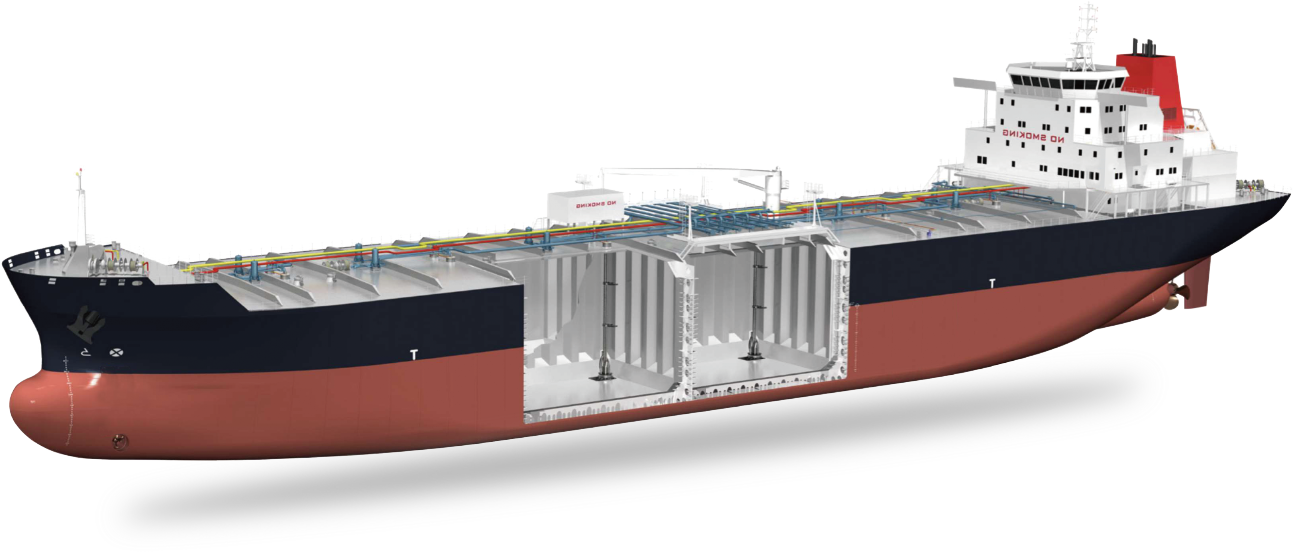

SERVICE PERFORMANCE ADVANTAGES

>300

Over 300 chemical tankers project service experience

Sweden Stena 49,000T chemical tanker

Formosa Plastics 49,000WT chemical tanker

Hengyi 49,600T chemical tanker

Norway ODFJELL's 38,000T duplex SS chemical tanker

KEY ADVANTAGES

-

1.ABUNDANT QUALIFICATION CERTIFICATES

All YADA products, from manufacture process, weld process to quality system that served for chemical tanker have been certified by Nine Class Societies (LR, ABS, DNV, BV, CCS, RS, NK, RINA, KR) and NORSOK-M650, ASME, Petroleum and Petrochemical industries, so as to meet various needs of customer.

-

2.COMPREHENSIVE TECHNICAL SERVICES

A professional design team of more than 100 people, from 3D modeling, stress analysis to the production ticket drawing, and discompose the components pallet according to the production ticket drawing at the mean time.

-

3.PROFESSIONAL OPTIMIZATION DESIGN

YADA has professional manufacture capacity of steel pipe, pipe fitting, flange, prefabricated pipe, can optimize the design from practical pipe manufacture perspective, so as to reduce the weld seam and enhance the quality of pipeline.

-

4.STANDARDIZED ASSEMBLY SERVICES

Nearly 10,000 square meters assembly workshop used for gathering and distribution of pallets, and preparation for prefabricated pipe production according to the pallet list of production ticket drawings.

-

5.ONE-STOP MANUFACTURING SERVICE

More than 20,000 square meters of specialized SS pipe prefabrication workshop, automatic welding takes more than 80% which achieves higher efficiency and qualification rate. YADA has 12 complete production lines, which can quickly response to supplement and non-standard parts caused by design alteration, and ensure on-time delivery of the project.

-

6.PERFECT QUALITY INSPECTION

The third level certified NDT team applying automatic film equipment and ferritic testing equipment imported from Germany, passivation film detector imported from Netherlands, and HD endoscope imported from Japan and other professional testing instruments, to ensure product quality.

-

7.ABSOLUTE PRICE ADVANTAGE

YADA commitment: under the same quality level, YADA has an absolute price advantage in the field of liquid cargo related system of chemical tanker, and can provide customers with more cost-effective related products and services.