SERVICE PERFORMANCE ADVANTAGE

-

SUBSEA TREE

Served CNOOC Dongfang 1-1 subsea Tree Project (pressure level: 64.9MPa)

-

OFFSHORE PLATFORM

Served CNOOC Dongfang 13-2 offshore engineering Platform Project (pressure level: 64.9MPa)

-

HIGH PRESSURE GAS

Served High pressure Gas Module for 178,000M3 LNG carrier to Imamji Shipbuilding (Pressure level: 40MPa)

KEY ADVANTAGES

-

1.FINITE ELEMENT ANALYSIS

According to customers' working conditions, the finite element analysis and simulation of different high-pressure pipe accessories were carried out.

-

2.RICH APPLICATION FIELDS

For FPSO, Marine engineering, petrochemical industry, nuclear power industry, hydrogenation plant and other industries, YADA can provide customers with a one-stop solution of high-pressure pipe and accessories.

-

3.PROFOUND TECHNICAL STRENGTH

Independent R&D of 4,000T bending machine and the world's first ultra-tonnage, ultra-thick and ultra-high pressure 25,000T integrated hydraulic forming equipment, further improved its high pressure pipe fittings R&D strength.

-

4.CONTINUOUS TECHNOLOGICAL EXPLORATION

It broke through the industrial difficulties such as bad forming process, unstable welding process and material properties after heat treatment during the manufacturing process of ultra-thick and ultra-high pressure duplex stainless steel in China, overcame a number of technical difficulties and realized the first domestication.

-

5.EXTENSIVE SERVICE CAPABILITY

Relying on independently developed and manufactured production equipment, YADA can provide customers with high pressure welded pipes with a maximum diameter of 1.8m and a thickness of 120mm, can make seamless pipe with a maximum diameter of 1.0m and a thickness of 100mm. YADA can make the biggest weld pipe with maximum diameter of 0.5~3.0 m and the thickness of 50~100mm.

-

6.FULL COVERAGE OF QUALIFICATION CERTIFICATES

The company has obtained nine class society certificates (LR, ABS, DNV, BV, CCS, RS, NK, RINA, KR), 39 international certifications (NORSOK-M650, ASME, API, food), and 6 industry certifications (petroleum, petrochemical, offshore, nuclear and shipbuilding). Full coverage of Austenitic stainless steel, Duplex steel, Super duplex steel and other materials, full coverage of welding process, pipe wall thickness and diameters.

-

7.PERFECT QUALITY CONTROL

Equipped with imported spectrometer, PMI detector imported and other professional testing equipment, carry out receiving inspection for all kinds of components and raw materials, manufacture process inspection and other quality indicators were tested with 100% full coverage. Professional inspectors control the whole process of product quality from QC planning, ITP review, inspection application to data submission.

-

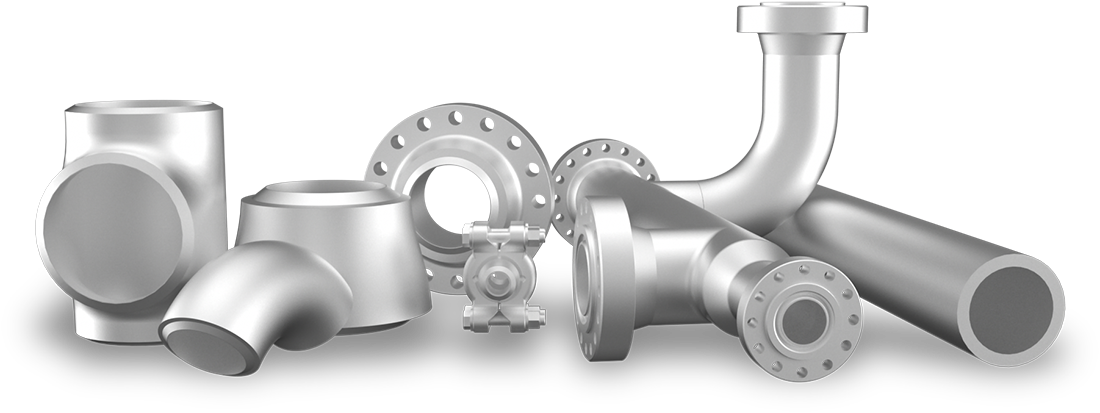

8.PRODUCT PARAMETERS