KEY ADVANTAGES

-

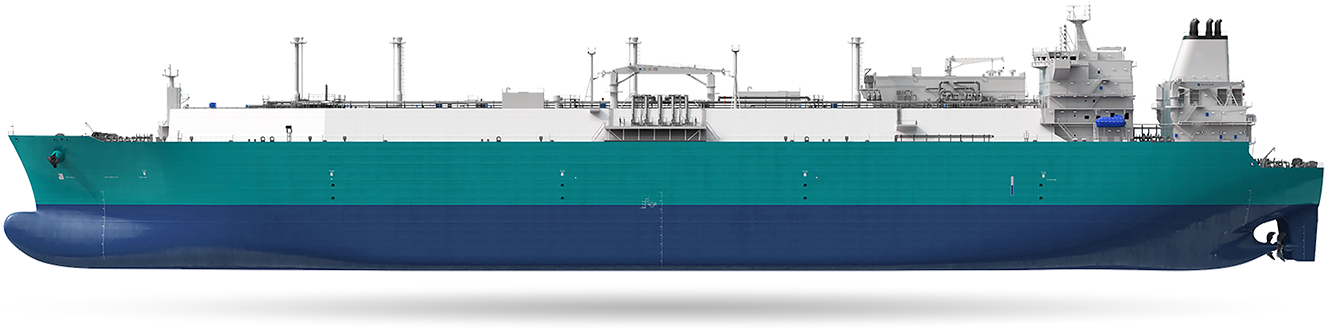

1.RICH GAS VESSEL SERVICE EXPERIENCE

From LEG, LPG to LNG, YADA has served more than 100 gas carriers and accumulated rich experience in gas carrier service, and has been highly recognized by shipyards, class societies and shipowners after operation.

-

2.ONE-STOP SERVICE FOR THE WHOLE LIFE CYCLE

We provide one-stop service of the whole life cycle from design, manufacture, installation, to operation and maintenance, which really makes the project operation achieves short and fast response within 24 hours.

-

3.TWELVE PRODUCT LINES WITH PERFECT CONFIGURATION

YADA has 12 product lines, from seamless steel pipe, welded pipe, pipe fitting, flange to bracket, prefabricated pipe, double-wall pipe, pump tower and module, which effectively guarantee the delivery of liquid cargo, gas, refueling, LNG tank and other systems with quality and quantity.

-

4.FULLY EQUIPPED WITH ADVANCED PRODUCTION EQUIPMENT

YADA has developed a series of professional automation equipment, in which the 25000 tons of ultra-thick ultra-high pressure hydraulic forming equipment is the world's first set. In addition, more than 80% weld seams on prefabrication line are automatically welded, which improves the efficiency and guarantees the quality.

-

5.PERFECT QUALITY CONTROL

Equipped with imported spectrometer, PMI detector imported and other professional testing equipment, carry out receiving inspection for all kinds of components and raw materials, manufacture process inspection and other quality indicators were tested with 100% full coverage. Professional inspectors control the whole process of product quality from QC planning, ITP review, inspection application to data submission.

-

6.STRICT AND EFFECTIVE QUALITY ASSURANCE SYSTEM

From incoming inspection of raw materials to process manufacturing and delivery of finished products, each process is carried out in strict accordance with the standard quality assurance system, and has obtained 39 international recognitions.

-

7.ABUNDANT QUALIFICATION CERTIFICATES

Welding process, welding quality, pressure testing process and other procedures and quality systems have been approved by ABS, DNV, LR, CCS, BV, RS, NK, RINA, KR, ASME, API, NORSORK and other international authorities, to meet the needs of different customers.