Served over 2,000 projects

-

Offshore industry

Saudi Aramco International Integrated Port Facility Project, CIMC Raffles D90 ultra-deep water semi-submersible drilling platform, Dongfang 1-1, Dongfang 13-2 CNOOC offshore engineering platform, etc.

-

Energy industry

LNG receiving station, filling station

-

Chemical industry

Wanhua Chemical, Hengyi Petrochemical, CNOOC Huizhou Refinery & Chemical 1.2 million tons/year ethylene project, Donghua Energy 1.2 million tons/year methanol project.

-

Shipping industry

LNG, LPG, FSRU, FPSO, chemical tanker, oil tanker

-

Nuclear power

Hainan Nuclear Power, Changjiang Nuclear Power, Qinshan Nuclear Power, etc.

KEY ADVANTAGES

-

1.FULL COVERAGE OF QUALIFICATION CERTIFICATION

The company has obtained nine class society certificates (LR, ABS, DNV, BV, CCS, RS, NK, RINA, KR), 39 international certifications (NORSOK-M650, ASME, API, food), and 6 industry certifications (petroleum, petrochemical, offshore, nuclear and shipbuilding). Full coverage of Austenitic stainless steel, Duplex steel, Super duplex steel and other materials, full coverage of welding process, pipe wall thickness and diameters.

-

2.PROFESSIONAL TECHNICAL TEAM

A professional installation team over 100 employees, specializing in structure, turbine, pipeline analysis, stress analysis, welding, machinery, automation, etc., can provide pipeline scheme design, modeling design, stress calculation, TDS submission and production design according to customer demand for skid products.

-

3.UNIQUE OPTIMIZATION SERVICE

To optimize the design of multi-pass pipe, extended elbow and other products from the manufacturing point of view according to the pipeline direction, so that reduces welding seams by 20%, improves the quality of pipeline system and extend the service life.

-

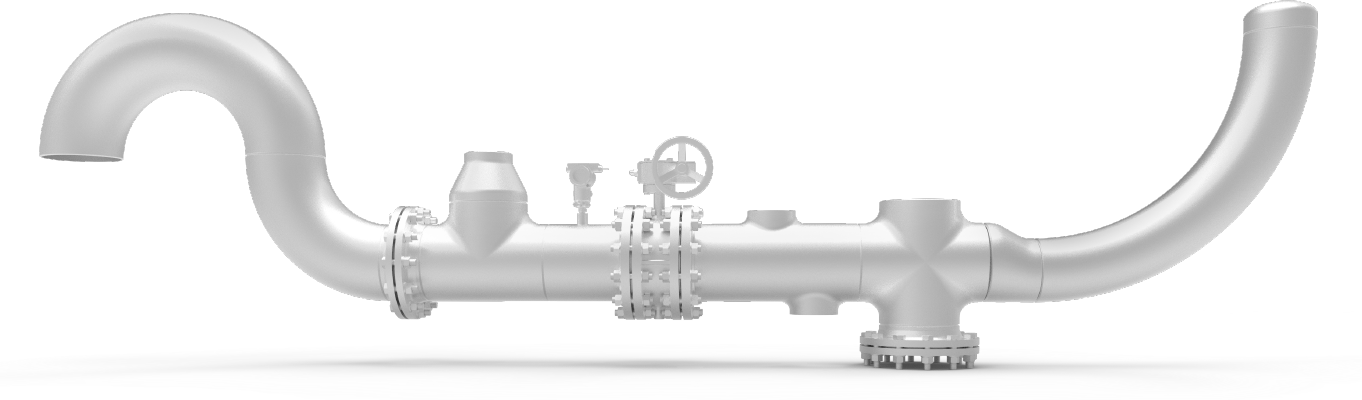

4.FULL PRODUCT CHAIN SERVICE STRENGTH

With welded pipe, seamless steel pipe, pipe fittings, flanges, joints, supports and other production lines, to achieve 100% full coverage of piping system components, quickly solve the design changes caused by additional parts, non-standard parts and other problems, so as to ensure the project timeline.

-

5.PROFESSIONAL PREFAB SERVICE

More than 20,000 square meters of professional SS pipe flexible prefabrication production workshop, orderly production according to the pallet, 80% weld seams use automatic welding, accomplish prefabrication, passivation and coating in one factory according to customer order demand.

-

6.PERFECT QUALITY CONTROL

Equipped with spectrometer imported from the United States, PMI detector imported from the United States, Metallographic microscope imported from Japan, Ferrite tester, Ray flaw detector& Eddy current flaw detector imported from Germany & ultrasonic flaw detector, passivation film detector imported from the Netherlands and other professional testing equipment, carry out receiving inspection for all kinds of components and raw materials, manufacture process inspection and key process verification, chemical composition, mechanical performance, metallographic structure, high-temperature & cryogenic resistance, corrosion resistance and other quality indicators were tested with 100% full coverage.

-

7.STANDARD FIELD INSTALLATION

A professional installation team over 300 employees provide customers with efficient and standardized on-site installation services, save customers' personnel costs and management costs, to ensure product quality.

-

8.ABSOLUTE PRICE ADVANTAGE

YADA commitment: under the same quality conditions, YADA has absolute price advantage in the field of one-stop flexible pipe prefabrication solution, can provide customer with more cost-effective products and services.